AUTOMATE 2025

WHERE INNOVATION MEETS SCALE

Kawasaki Robotics is exhibiting at AUTOMATE with a singular goal: showing that the FUTURE is now. We’ve pushed ourselves, and now we’re giving a boost to our customers—and the industrial robotics industry as a whole.

Going to AUTOMATE this year?

Let us know you’ll be stopping by the Kawasaki booth!

THE PLACE TO BE

On top of the incredible equipment and technology, the Kawasaki Robotics booth will showcase how creative and forward-thinking ideas can be executed on a large and impactful scale.

It is not just about having groundbreaking ideas or developing new concepts, but also about the infrastructure, resources, and capability to implement those ideas broadly and efficiently. At its core, this is what Kawasaki Robotics is about, helping customers grow and expand successfully.

TECHNOLOGY AT AUTOMATE 2025

A LINEUP OF DIFFERENCE-MAKERS

Next up from Kawasaki Robotics: jaw-dropping technology strong enough to lift the industry up.

THE FUTURE NOW

A TRIO OF ROCK STARS

Just a taste of the incredible capabilities of our integration partners

Crown Battery

Pairing engineering principals with common sense is what sets KJ Engineering designs apart and why Crown Battery chose to work with them .

Hammond Roto Finish

Since 1881, Hammond Roto-Finish has pioneered new innovations in the polish & buff and mass finishing sectors of manufacturing.

Shearer’s Foods

Shearer’s Foods trusted full stack, integration and manufacturing firm JMP Engineering to build their first system, and it won’t be the last.

GOT A QUESTION?

WHY KAWASAKI ROBOTICS

A SERVICE-BASED APPROACH &

MANUFACTURER MINDSET

fi

Over 100 years of manufacturing expertise go into our robot arms

Most application-specific options come standard

Patented internal dress design for easy installation and maintenance with minimized wear

Our open architecture and hardware-agnostic stance allow us to work with the best technology in the world

No hidden costs for software, manuals, training, remote service calls, etc.

We offer through-life engineering services

Exclusive online resources and tools, free to Kawasaki customers

FIND IT IN BOOTH 3218

STILL NOT CONVINCED?

KAWASAKI IN MOTION

WATCH ON YOUTUBE

IT’S DIFFERENT AT KAWASAKI

THE ROBOTS

Thoughtfully designed, built to last and always tech-agnostic.

THE IMPACT

A superior model that harnesses collaboration and partnership.

THE ROBOTS

THE PEOPLE

A down-to-earth team with sky-high knowledge to share.

THE TECH

Frequent innovation that pushes what industrial robotics can do.

CASE STUDY

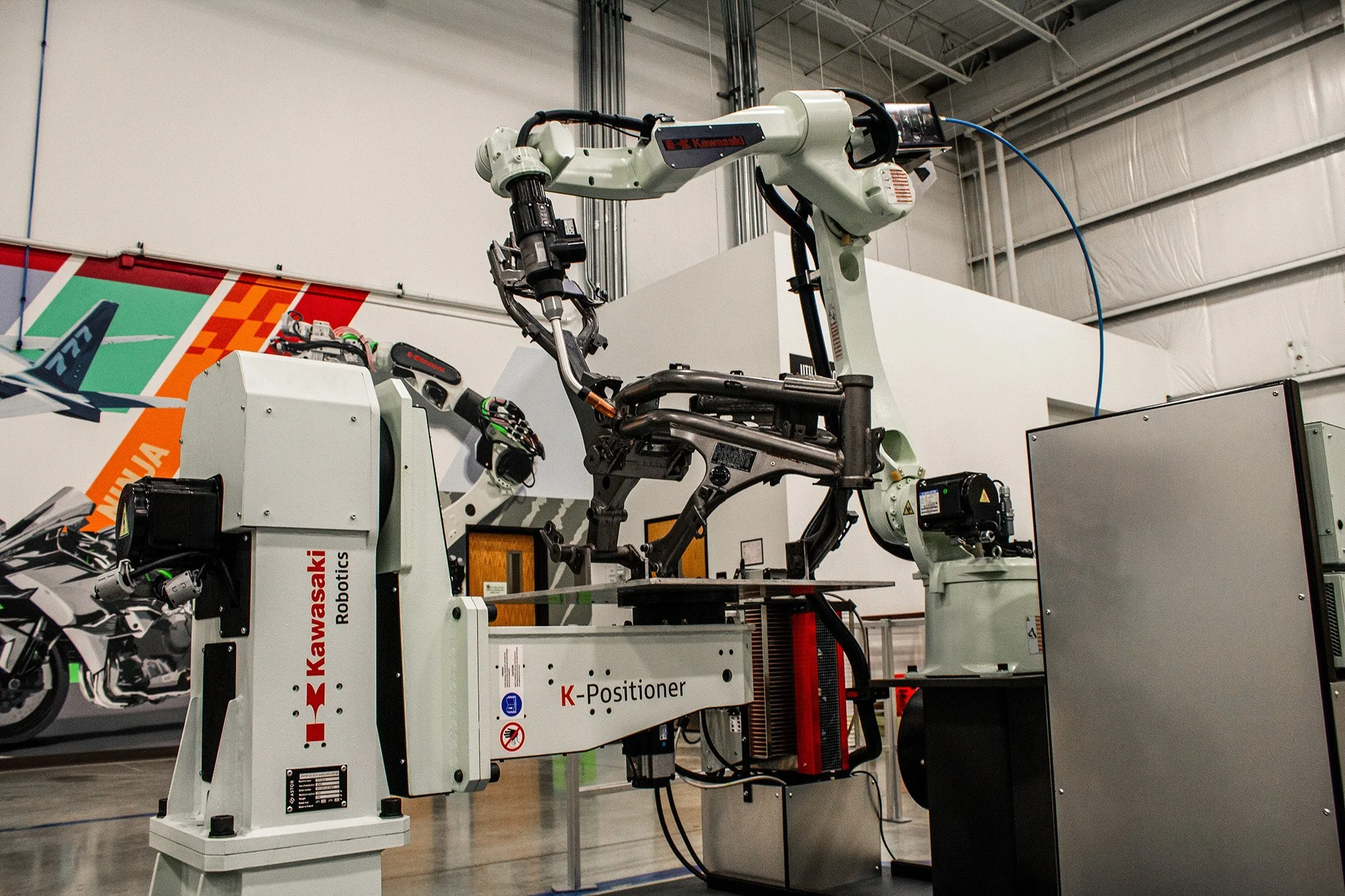

ROBOTIC ARC WELDING

Experienced welders are scarce and customer demands are plentiful. Robotic welding can bridge that gap, and at Kawasaki Motors Manufacturing Corp., robot welding has been in place since the 1980s. Today, over 80 robots are welding at KMM, and we have the results from those decades of work.

30

Years of robotic arc welding at KMM

80%

The amount of arc welding done by robots

FAQs

-

HOW TO FIND US

Viewing Booth:

3218 - 50 x 40 - Exhibit Hall A-Dhttps://automate25.mapyourshow.com/8_0/exhview/index.cfm?selectedBooth=3218

Headquarters:

28140 Lakeview Drive

Wixom, Michigan 48393

United States

https://kawasakirobotics.com/ -

-

CAN’T-MISS STUFF AT AUTOMATE

Check out all of our partner booths, from vision suppliers to integration partners.

MORE QUESTIONS?

Ask away! We’ll get right back to you—and maybe even add your question to the FAQ.

HEAR FROM THE CUSTOMERS

“For us, the attractive price, the robust design and the specific but precisely fitting requirement profile of the robot were the deciding factors. With a proven Kawasaki partner in the neighboring town, the available service was also excellent for us. And the technical support provided by Kawasaki itself has quickly proven to be particularly reliable and flexible”

Technical director at Haase Tank GmbH

Whether you want to chat about AUTOMATE, ask a robotics-related question or just tell us how spectacular this landing page is, we’re all ears. Fill out the form below and we’ll get back to you.